Discovering Cutting-Edge Foam Control Technologies for Sustainable Practices

Discovering Cutting-Edge Foam Control Technologies for Sustainable Practices

Blog Article

The Duty of Foam Control in Enhancing Product High Quality and Effectiveness

Foam control is an often-overlooked yet crucial component in the search of item top quality and functional effectiveness throughout varied markets. This conversation will explore the multifaceted effect of foam on both product stability and production processes, raising necessary inquiries regarding the methods that can be used to maximize foam control.

Comprehending Foam Formation

Foam formation is an intricate sensation that can significantly influence item high quality and functional effectiveness across various industries. It occurs when gas bubbles become trapped in a liquid, causing the development of a foamy structure. A number of factors add to this procedure, including the physical and chemical homes of the liquid, the presence of surfactants, and the conditions under which mixing happens. Recognizing these variables is vital for handling foam properly.

The liquid's viscosity and surface area tension play essential duties in foam stability. Surfactants, as an example, can minimize surface area stress, promoting bubble formation yet likewise enhancing foam security, which can be bothersome in particular applications. Furthermore, mechanical agitation, temperature variations, and the visibility of impurities can intensify foam generation, making it important to monitor these aspects throughout manufacturing procedures.

Industries such as food and drink, drugs, and chemical production should be especially vigilant pertaining to foam control. By grasping the hidden systems of foam formation, companies can execute targeted methods to reduce its impacts, therefore maintaining functional efficiency and making sure regular product efficiency.

Influence on Item Top Quality

The existence of foam can significantly jeopardize product quality throughout numerous sectors. In producing procedures such as food and beverage, pharmaceuticals, and cosmetics, excessive foam can lead to inconsistent item solutions. For circumstances, in food production, foam may catch air, impacting structure and taste, which can inevitably change customer assumption and fulfillment.

Furthermore, foam can prevent the harmony of coatings and paints, leading to issues like bubbles and uneven finishes. In pharmaceutical applications, foam can interfere with the accurate dosing of fluid medications, possibly impacting restorative efficacy and client safety and security. These high quality concerns not just diminish the end product's appeal but can likewise lead to pricey recalls and damage to brand online reputation.

In addition, the existence of foam can complicate quality control actions, making it tough to achieve specific measurements and constant results. Effective foam control not just mitigates these risks however likewise enhances general product high quality by making certain that formulations satisfy strict industry requirements. By purchasing foam control strategies, companies can protect their products, improve customer satisfaction, and maintain an one-upmanship in the marketplace.

Operational Difficulties From Foam

Effective operations in different sectors can be severely interrupted by the presence of foam, which presents several difficulties throughout production procedures. Foam can hinder mixing and reaction times, impeding the efficiency of chemical processes. In industries such as food and drink, foam development can bring about imprecise fill levels, resulting in item waste and disparities in packaging.

In settings where hygiene is vital, such as pharmaceuticals and food processing, foam can make complex cleansing procedures, developing covert storage tanks for pollutants. This not just raises high quality problems yet likewise can lead to compliance concerns with regulative requirements.

Moreover, the emotional impact on drivers can not be ignored; too much foam can create a chaotic workplace, bring about lowered spirits and performance. In recap, dealing with the functional difficulties positioned by foam is essential to maintaining efficiency and product high quality in different markets.

Techniques for Effective Foam Control

Exactly how can markets effectively minimize the difficulties posed by foam? Reliable foam control methods are vital for enhancing product top quality and operational performance. One main approach is using defoamers, which are chemical representatives designed to lower or remove foam development. Picking the suitable defoamer requires a comprehensive understanding of the details procedure problems and the materials entailed. read the article

Along with chemical solutions, process optimization plays an important function in foam administration. Industries can evaluate and change parameters such as blending temperature, rate, and stress to lessen foam generation. Carrying out tools alterations, like setting up foam-breaking tools or adjusting container style, can even more help in reducing foam degrees.

Normal tracking and evaluation of foam actions within production procedures are likewise essential. Using sophisticated sensors and analytics can supply real-time data, permitting prompt interventions and modifications. Personnel training is just as crucial; making sure that employees are well-informed regarding foam dynamics and control techniques can lead to positive foam monitoring.

Study and Industry Applications

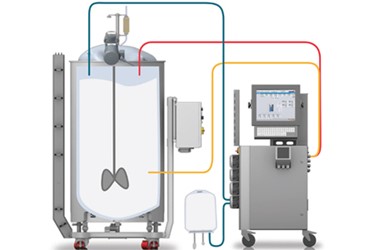

While lots of industries face distinct obstacles associated with foam control, case researches reveal that customized methods can significantly boost both product quality and operational performance. In the pharmaceutical industry, for instance, a leading manufacturer executed a personalized foam control method that decreased foam formation throughout fermentation processes. This innovation not only improved yield by 15% yet also decreased contamination risks, guaranteeing higher item stability.

Similarly, in the food and beverage industry, a significant dairy producer challenged excessive foam during pasteurization - Foam Control. By presenting a specialized antifoam agent, they decreased processing time by 20%, which directly converted to increased throughput and lowered energy consumption. The application of foam control measures ensured regular item appearance and preference, reinforcing brand name loyalty

In the chemical production sector, a study highlighted the successful application of foam control in wastewater therapy processes. The execution of a real-time tracking system enabled operators to readjust antifoam dosage dynamically, resulting in a 30% decrease in chemical usage and improved effluent quality.

These study show the varied applications of foam control throughout markets, stressing its critical function in enhancing item quality and functional efficiency.

Final Thought

Finally, efficient foam control is essential to improving item quality and functional effectiveness throughout various sectors. By addressing foam formation, businesses can reduce the negative influence on formulas, texture, and dosing precision. Applying targeted foam monitoring approaches not only lowers processing hold-ups and waste yet also reinforces equipment dependability. Ultimately, you could try here prioritizing foam control adds to improved productivity, protecting brand reputation, and raising consumer satisfaction, highlighting its significance in quality control within manufacturing processes.

Foam control is an often-overlooked yet important element in the search of product high quality and operational effectiveness across diverse markets. Team training is equally crucial; making certain that personnel are educated regarding foam dynamics and control techniques can lead to proactive foam monitoring.

While numerous sectors face unique challenges related to foam control, situation studies expose that customized techniques can significantly improve both item quality and operational performance (Foam Control). In the pharmaceutical market, for circumstances, a leading manufacturer executed a custom-made foam control technique that minimized foam formation throughout fermentation procedures.In conclusion, effective foam control read this post here is important to improving product top quality and operational effectiveness throughout numerous sectors

Report this page